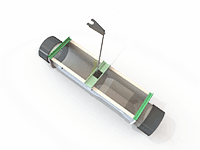

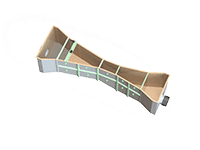

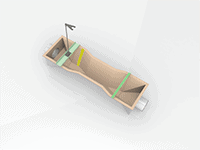

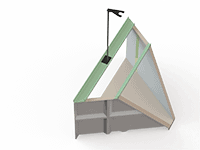

Flumes are specially designed static structures or fittings that restrict the flow of fluid by narrowing the available passage area within a system. These simple components measure and monitor the flow of fluid in free-flowing conditions. The flume can accelerate flow rate through changes in its elevation, the shape of the floor, and the narrowing of system sidewalls, which can transform a subcritical flow of fluid to a critical or even supercritical flow that operators can easily measure. With a variety of standard and custom flume types available, industries can choose the type that best fits their application.

Advantages of Fiberglass Flumes

Selecting the right flume for an application’s environment, flow rate, and channel type allow that application to capitalize on the key benefits of using flow measurement flumes. These include:

- Control over fluid flow rate with high- and low-rate capabilities

- Versatility, as they come in various sizes and shapes

- Less head loss and easier debris passage in the stream of fluid compared to weirs

- Accuracy in making flow predictions

- Few maintenance requirements due to self-cleaning

- Easy installation with a compact footprint

- Readily available, including installation components

Fiberglass flumes give the flume more structural integrity and easy maintenance characteristics across diverse operating conditions and fluid types. The resin and glass fiber construction gives fiberglass some unique advantages for flume composition, including the versatility and malleability of the material. Fiberglass flumes also come in a wide range of shapes and colors for different operations. Properties of fiberglass that make it an excellent choice for flumes include:

- Mechanical strength, despite its lightweight

- Cost-effectiveness

- Resistance to corrosion from chlorine and other chemicals or contaminants

- Thermal, electrical, flame, pest, and microbe resistance

- Ability to resist UV radiation damage with a gel coating

Flume vs. Weir

Both flumes and weirs control the open channel flow of fluid through a designated pathway. However, the way in which they guide and manage fluid flow is very different. Fluid passes through a flume, and fluid passes over the top of a weir. That dissimilarity in weir construction can introduce inertia in the fluid, reducing its head to approximately a quarter of that retained by a flume installation. Weirs have a dam plate that allows liquid pooling and results in lost force, as well as more frequent maintenance. Flumes, on the other hand, guide fluid and increase the force of its flow without significant head loss or lost potential. Flumes offer a better solution for moving fluid through a flat or low-gradient system of channels and ditches.