Fiberglass reinforced plastic (FRP) fans are specifically designed to capture, move, clean, and vent moist or corrosive air. Combining the best features of fiberglass and thermoset polymers, their composition is ideal for harsh industrial applications.

Learn more about the benefits, applications, and types of FRP exhaust fans, including the fans we offer here at VPC Fiberglass.

Benefits of Using Fiberglass Reinforced Plastic (FRP)

FRP fans play a crucial role in keeping the air in industrial environments clean and safe for workers. Here is a look at the main benefits of using FRP fans:

- Corrosion resistance: FRP fans combine glass fibers and thermoset polymers to produce a higher level of corrosion resistance than present in the individual materials. These fans are comparable to stainless steel fans in terms of resisting chemically corrosive air and perform even better at handling air that is corrosive to certain alloys.

- Fire retardance: CFT fans are all constructed with fire retardant resins which greatly reduces the risk of fire.

- Cost-effectiveness: Compared to stainless steel and exotic metal fans, FRP fans are an effective and affordable alternative. Coupled with the long life of fiberglass, these fans are a worthy long-term investment.

Industrial Applications of FRP Fans

Fiberglass exhaust fans have seen significant adoption in the industrial sector due to their corrosion resistance. Both private and public sector organizations—including the U.S. departments of health and defense—utilize these fans to exhaust caustic environments. These are the main applications for FRP fans:

- Oil and petroleum refineries

- Power generation units

- Indoor swimming pools

- Textile mills

- Pharmaceutical facilities

- Fertilizer plants

- Cement facilities

- Wastewater treatment

- Fume scrubber systems

- Aquariums

Axial vs. Centrifugal Fans

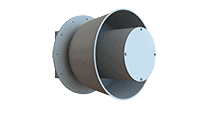

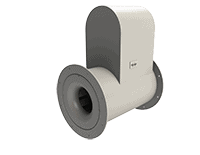

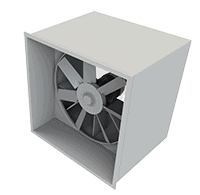

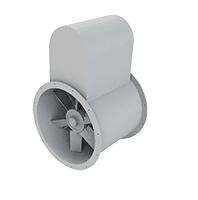

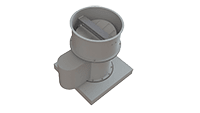

There are two types of industrial FRP fans: axial and centrifugal fans. Axial fans have blades that rotate around a central axis, drawing and pushing air outward—parallel to the axis. They can achieve high flow rates, but airflows are low pressure.

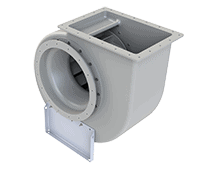

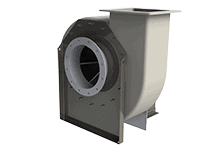

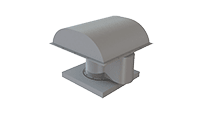

Centrifugal fans blow air at right angles to the fan’s intake. The fan wheel uses centrifugal force to pull in and increase the pressure of the incoming air, producing a steady, high-pressure airflow.

Your specific application will determine whether you require axial or centrifugal FRP fans.

Premium FRP Fans at VPC

At VPC fiberglass, we supply premium, high-quality fiberglass products, including fiberglass reinforced plastic fans. FRP fans from Composite Fan Technology are the ideal solution for commercial environments. They are highly corrosion-resistant, rugged, efficient, and low maintenance. Here is an overview of our axial and centrifugal fiberglass fans: